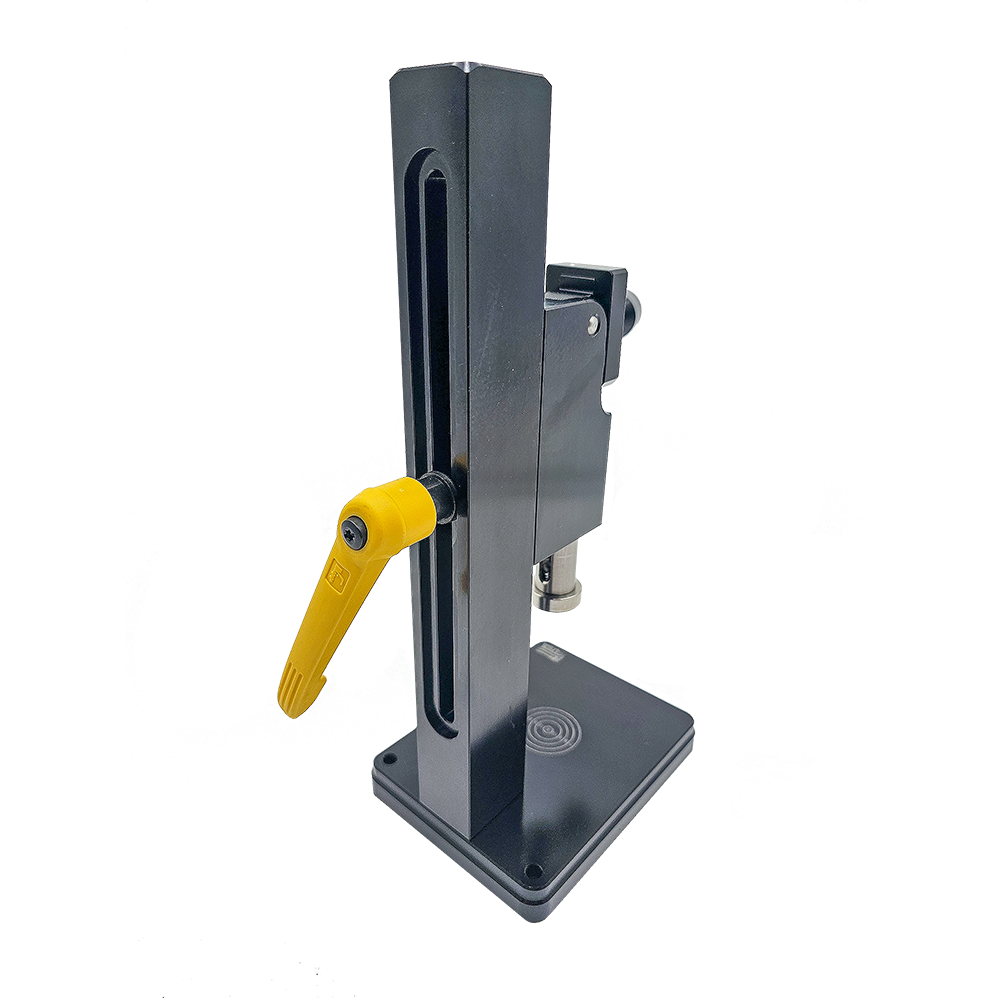

LE Wilson Reloading Arbor Press

L.E. Wilson Precision Arbor Press

The new L.E. Wilson Precision Arbor Press is a result of decades of designing, engineering and manufacturing precision tools for the discriminating handloader. Our arbor press is designed to also work with L.E. Wilson Inline Bullet Seating Dies which are the industry Gold Standard among precision seating dies. It will also work for other brands of hand style seating dies as well. The L.E. Wilson Arbor Press will also with our other engineered reloading tools such as our neck sizing dies with interchangeable bushings, our punches and bases for ejecting primers in a separate operation, and also to press cases in and out of holders for use on Wilson Case Trimmers.

This arbor press gives the handloader exceptional feel and control of the seating operation. Central pivot mechanism delivers an impressive force through a smooth 90-degree rotation. The cam-over feature serves two important functions: it simplifies height adjustments and maximizes leverage at the critical moment. This arbor press has enough adjustment range to handle everything from the smaller 17 calibre seaters up to the larger cartridges such as the 408 Chey Tac. The innovative V-channel design in the guide rail prevents unwanted upward movement during operation but at the same time allows easy adjustments to height.

Features:

- Cam-over mechanism provides incredible leverage for a small package but more importantly provides incredible feel for the seating operation in regards to neck tension.

- Ergonomic design makes loading bullets an easy and comfortable operation.

- Stable aluminum baseplate with engraved alignment target for ease in centering seater

- Full one inch of throw distance which exceeds most industry standards

- Seven inches of height adjustment to accommodate all L.E. Wilson seaters

- Six-inch reference scale for precise height adjustment which can be noted for use with various seaters

- Precision machined arbor cap has a self-centering dimple for perfect punch alignment in decapping operations

- Every component has been engineered not only for performance but for longevity.

- Our commitment to in-house manufacturing and assembly gives us complete quality control over each and every component.

- Continuing the high standards for precision craftsmanship established decades ago by our founder Sam L.E. Wilson!

- MADE IN THE USA. All machining and assembly operations are performed inhouse at their East Wenatchee, Washington facility. Patent Pending.

Specifications:

- Main components – machined from billet aluminum

- Turned components – machined from 303 stainless steel

- Aluminum parts are hard coat anodised

- MIL-A-8625 Type III - This is a military specification for a very hard, durable and corrosion-resistant finish which is thicker and more wear-resistant than normal Type II anodising.

- Industrial grade finish ensures your press will maintain its appearance and function for many years of regular use

- Height – 11.85”

- Baseplate dimensions – 5.50” x 4.25” x 0.735”

- Weight – approximately 4.5 lbs.

LE Wilson Arbor Press spec sheet